What are Key Tank Body Aluminum Alloys

5083 aluminum plate belongs to the Al-Mg (aluminum-magnesium) alloy family, with a magnesium content between 4.0% and 4.9%, strengthened by elements such as manganese and chromium. It is a typical rust-resistant aluminum alloy. Its core advantages and adaptability to tank truck application scenarios are:

Firstly, lightweight, with a density of only 2.66 g/cm³, reducing weight by approximately 40% compared to carbon steel tanks, effectively reducing fuel consumption and tire wear, and improving transportation economy.

Secondly, strong corrosion resistance; the synergistic effect of magnesium and manganese forms a dense oxide film that resists corrosion from fuel, chemical media, and the atmospheric environment, extending the tank's service life.

Thirdly, excellent weldability; the weld strength retention rate can reach over 90% of the base material, meeting the requirements for tank sealing and structural integrity.

Fourthly, good mechanical properties; strength and plasticity can be adjusted through different heat treatment states to adapt to the functional requirements of different parts of the tank.

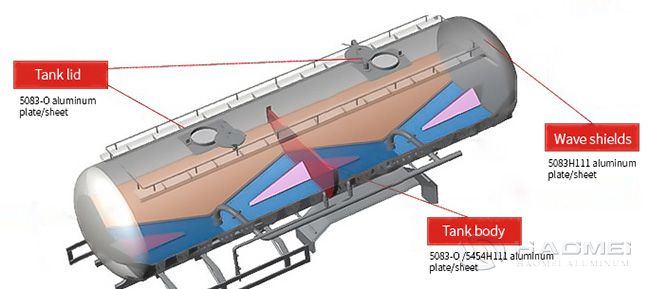

5083-O and 5083-H111 are two key states formed through different processes. Their performance differences directly determine their respective applications on the tank body. They complement each other, forming the core material system of tank truck bodies.

5083-O aluminum

EN AW 5083 o, obtained after full annealing, is a soft alloy. Its core performance characteristic is excellent plasticity, making it more suitable for parts of the tank body that require complex forming but do not need to withstand high-strength loads. The core applications of 5083-O are mainly in three areas:

- Tank end caps (heads): The end caps at both ends of the tank body are arc-shaped or spherical, typical complex forming components. They require materials with extremely high plasticity to adapt to bending processes, while maintaining shape stability after forming to avoid cracking due to stress concentration. The soft characteristics of 5083-O perfectly match this requirement, perfectly fitting the forming process of the end caps and ensuring a tight seal between the end caps and the tank body.

-Baffles (Surge Brakes): When tank trucks transport liquid goods, surge braces (surge braces) are typically installed inside to reduce the impact of liquid sloshing on the tank body. These components need to be cut and bent according to the internal space of the tank and must possess a certain degree of cushioning. The easy machinability and good plasticity of 5083-O meet these molding requirements and effectively absorb the impact force generated by liquid sloshing, protecting the tank structure.

-Side Covers/Inspection Covers: Side covers or inspection covers on both sides of the tank truck need to be frequently opened and closed, and their shapes are often irregular curved surfaces, requiring multiple bending processes. The soft and easily moldable nature of 5083-O reduces processing difficulty, while its good toughness prevents fatigue fracture caused by frequent opening and closing, ensuring the durability of the components.

5083 H111

5083-H111 aluminum alloy is formed after annealing and light cold working, belonging to a lightly work-hardened state. Its performance characteristics are a perfect balance between strength and plasticity. Its robust and balanced performance makes it the preferred material for the core load-bearing components of tank truck bodies.

The core applications of 5083-H111 are concentrated in the critical areas of the tank body that bear the main loads:

- Tank Body (Tank Body): The tank body is the core load-bearing component of the tank truck, needing to withstand the weight of the cargo, vibrations and impacts during transportation, and the pressure of the internal medium. This places extremely high demands on the material's strength, toughness, and weldability.

The high strength of 5083-H111 ensures the stability of the tank body structure and resists various load impacts. Its excellent weldability allows for seamless splicing of multiple aluminum plates (typically, a tank body requires 4-6 aluminum plates welded together), ensuring the tank's sealing and overall strength. Currently, the mainstream thickness of 5083-H111 aluminum plates used for tank bodies is 4-8mm, with a width up to 2650mm, adaptable to the manufacturing needs of tank trucks of different capacities.

- Tank Body Support Structure Auxiliary Components: In addition to the tank body, auxiliary load-bearing components such as the support beams at the bottom of the tank and the guardrail brackets at the top are also commonly made of 5083-H111. These components need to work with the tank body to bear the overall load, and at the same time, they need to have a certain resistance to deformation. The high strength and fatigue resistance of 5083-H111 can meet the requirements of its use and ensure the stability of the overall structure of the tank.

Original Source:https://www.aluminumtankerplate.com/a/what-are-key-tank-body-aluminum-alloys.html

Tags: 5083 aluminum plate ,