Aluminum Sheet for Tanker Body

Why choose aluminum sheet for tanker body

At present, there are two kinds of metals for the manufacturing of fuel tankers: carbon steel and aluminum. In the transportation of gasoline, diesel and other oil products, especially for gasoline, the use of carbon steel tanks is easy to rust and needs anti-corrosion improvement, otherwise it will contaminate the oil.

At present, there are two kinds of metals for the manufacturing of fuel tankers: carbon steel and aluminum. In the transportation of gasoline, diesel and other oil products, especially for gasoline, the use of carbon steel tanks is easy to rust and needs anti-corrosion improvement, otherwise it will contaminate the oil.

With the continuous improvement of environmental protection and fuel saving and overload control measures for commercial vehicles, people’s acceptance rate of tankers with high configuration is gradually increasing, and the calculation of operating costs is more rational. The light-weight aluminum alloy tank truck with high safety, light weight, and large standard transport loads has been promoted worldwide.

The aluminum sheet for tanker body is not only of light weight, but also high strength. In fact, aluminum alloy has been widely used in aerospace, ships, high-speed rail and other fields that require high strength.

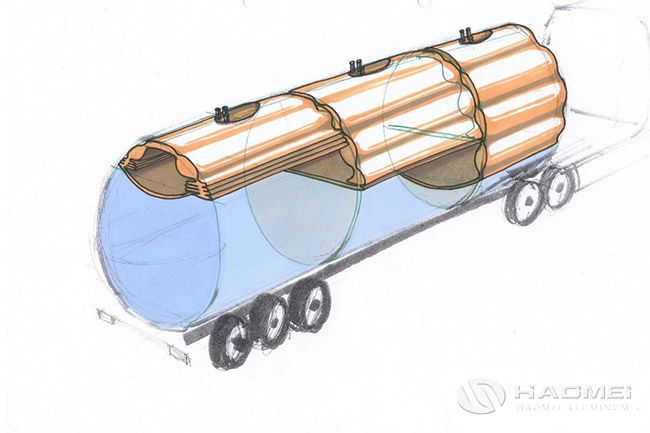

Structure of Aluminum alloy load tanker

It is mainly composed of oil tank, filling port, oil drain valve, manhole cover, oil hose, grounding chain, etc. Most of the tanker body is made of aluminum alloy. The two ends of the tank are sealed by heads, and the middle is a tank with an oval cross-section. The tank body consists of bulkhead, wash board and corresponding supports. The upper part of the tank is provided with a protective fence.

The lower part of the tank is welded with a pipe support and a bottom valve seat hole. The wall thickness of the tank should be greater than 3.2 mm, and the surface of the tank should be sandblasted first, and then zinc coated.

The manufacturing of tanker body

The aluminum alloy tanker body is made of aluminum alloy plates through bending, cold stamping and welding. The cylinder of the aluminum alloy tanker is the core part of the aluminum alloy load tanker.

The loading amount is determined by the size of the cylinder. The aluminum alloy tanker cylinder is made of 6mm thick aluminum plate. After the aluminum sheets are cut to standard size, they need connecting through the can coiling machine and then fixing by welding.

Alloys of aluminum plate for tank cylinder

5454 aluminum sheet is of good corrosion resistance, which was used in tank trucks in the early 1950s. 5083(Europe), 5454(USA) and 5182 are currently commonly used aluminum alloys for making tank cylinder. The non-flammable properties of aluminum can improve safety in the case of vehicle collision.

5182 aluminum sheet is specially developed for the storage and transportation of dangerous goods. It meets the latest ADR (Agreement for the Transport of Dangerous Goods on Highway) regulations.

When making tanks with a diameter less than 1.8 meters, the minimum thickness can be 4mm; When the tank diameter is larger than 1.8 meter, the minimum thickness of 5182 aluminum sheet can be 5mm.

Specifications of aluminum plate for tank body

Specifications of aluminum plate for tank body

Alloy | Thickness(mm) | Width(mm) | Length(mm) |

5083 | 2.0-8.0 | 1000-2000 | 2000-12600 |

5754 | 2.0-8.0 | 1000-2000 | 2000-12000 |

5454 | 2.0-8.0 | 1000-2000 | 500-16000 |

5182 | 4.0-7.0 | 20-2650 | 500-16000 |

5059 | 1.0-500 | 20-2650 | 500-16000 |

Original Source:https://www.aluminumtankerplate.com/aluminum-sheet-for-tanker-body

Tags: aluminum sheet for tanker body , aluminum plate for tanker body , aluminum plate for tanker cylinder